Production of pistons

In recent years, the rope pump has been introduced in various places in developing countries. The success of Nicaragua, which now has over 80,000 handropepumps, is known in an increasingly wide circle. Of course, the rope pump is not yet fully developed. New variations are being devised, such as versions powered by a windmill, bicycle or diesel engine.

The WOT is looking for ways to make piston manufacturing easier, faster and cheaper. Plastic appears to be a good alternative to rubber because it is less susceptible to wear.

To produce the pistons from plastic, an injection molding machine has been designed that can be viewed in the Kiwanda. The injection molding machine can be used to make pistons from waste plastic, such as broken plastic garden chairs. The current injection molding machine is a second version.

This injection molding method has the advantage that no electricity is needed for the production of the pistons, after all, the heating of the plastic is done with gas or another fuel. In addition, the cooling water flows past the molds due to the natural circulation of the water. If no polyethylene granules are available, plastic bags and other residual material can also be recycled.

Operation of the injection moulding machine

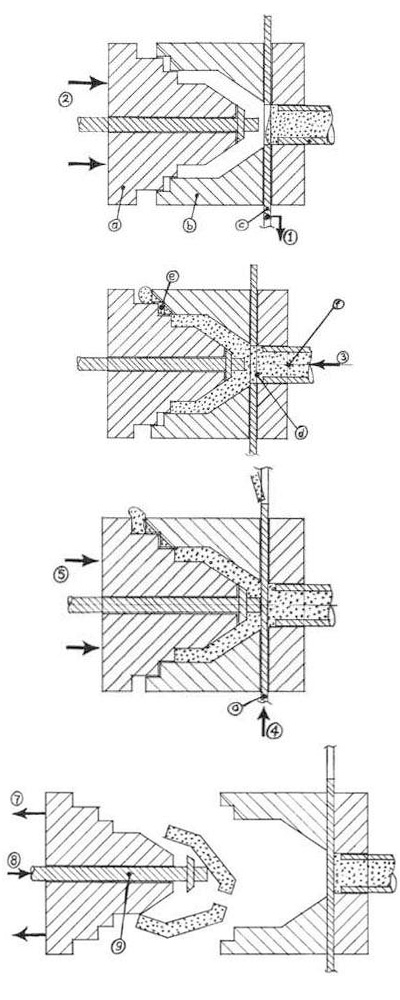

1. The valve (c) is opened.

2. The two moulds, a male (a) and a female (b), are almost completely closed.

3. The moulds are filled through the filling opening (d) with the viscous liquid until the plastic comes out through the vent hole (e).

4. The valve is closed.

5. The moulds are fully closed to obtain holding pressure as the plastic shrinks while cooling.

6. Water which circulates by the moulds keeps them at a temperature of around 60ºC. The plastic solidifies.

7. The moulds are opened.

8. The ejector (g) ejects the product from the moulds. The cycle is ended and the next piston can be made.

Simple version

It is also possible to do the injection molding with a simplified version of the above arrangement. In the system shown in the photo, the tube with the PE granules is heated with a gas torch. The molten plastic is pressed into the mold with a lever. Because there is no water cooling here, it takes longer for the piston to cool sufficiently, giving a longer cycle time.

This simple system is produced, among others, by Ludo Engineering in Polsbroek, which is led by Dolf Huebers. The device can also be made locally quite easily.