Piston Pumps General

One of the primary requirements for survival for people in developing countries is safe access to a supply of clean water. Open sources of water are easily contaminated with bacteria or viruses if they are in direct contact with the open air.

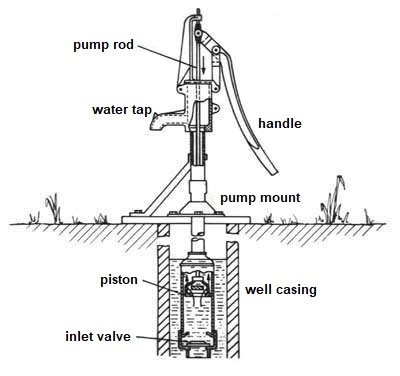

To make sure people only use clean drinking water, usage of a well with a lid on top or groundwater is advised. To get access to this groundwater a (hand)pump is required. An example of a handpump that utilizes a piston is shown in the figure on the right.

In the past, some unfortunate drawbacks of hand pumps came to the surface. Oftentimes they are not maintained properly, which makes them more difficult to use or even unusable over time.

Because of their sturdy design, building a hand pump can cost around $800 which means they are only a viable option if multiple families chime in to split the cost, which usually leads to a lack of clarity in regards of who owns the pump and who is responsible for the maintenance of the pump.

This, in turn, tends to result in a pump breaking, without anyone taking responsibility for the repairs.

Sometimes hand pumps are not built properly, are built using the wrong technology, are built on location without access to water or places where the groundwater level is too deep to be reached.

Communities are hardly involved in the preparation or implementation of handpump building projects, if they are involved at all.

The WOT is primarily interested in the development and distribution of pumps that are affordable and can be produced locally, such as the rope pump (which is in fact not piston-powered) as well as the EMAS pump.

The advantage of these pumps is that a single family can afford them, which solves the maintenance issue.

The WOT terrain is home to 2 working suction pumps, a couple of rope pumps and an EMAS pump.

Operation of a piston pump

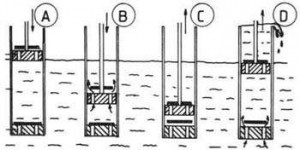

The most widely used pump is the single-piston pump, which consists of one piston, one cylinder, and two valves: the piston valve and the base valve. In step A, the piston is placed at the top dead center (the highest position it can be in), and is moving downwards, causing the piston valve to open and the base valve to shut. as the piston keeps moving downwards (as seen in step B) water will flow to the top side of the piston. Once the piston reaches its lowest point (bottom dead center) and starts moving up (as seen in step C), the piston valve will shut while the base valve opens. We’ve reached step D where the piston moving upwards will “pull” the water that’s on top of it with it, whilst also sucking in water at the bottom side through the base valve.

Besides single-piston pumps, dual-piston pumps also exist. These pump water when moving both up and down. They have a vastly more complicated valve system in comparison to their single-piston counterparts. Dual-piston pumps are not widely used.