The Hydraulic Ram (General)

The hydraulic ram is a pump that uses hydropower to pump. For example, a ram can be used in a river with a small drop in height to pump water to greater heights, for example, for household use and irrigation. The principle is that running water in a tube is suddenly stopped by closing a valve. The kinetic energy of the water is used to pump a little water up to a much higher height, up to thirty times higher than the drop of the water.

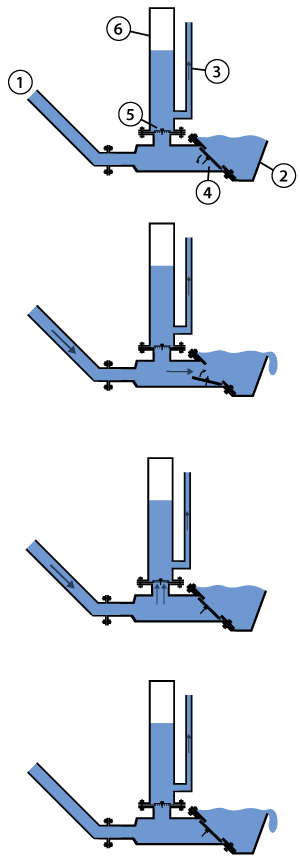

The figure on the right explains the principle in detail. The entrance to the hydraulic ram is on the left. This entrance is connected to a tube of about 10 meters long, in which water flows from a higher point, for example from a higher point of a stream. This can be achieved, for example, by constructing a small dam in a river, or by digging a branch canal along the bank.

Operation

When the valve on the right opens, the water from the pipe starts to flow into the hydraulic rams house and flows out through the valve on the right. The speed of the water in the tube increases rapidly until the water flows so fast that the valve on the right is lifted and closes. As a result, the flowing water closes its own exit.

When the valve on the right opens, the water from the pipe starts to flow into the hydraulic rams house and flows out through the valve on the right. The speed of the water in the tube increases rapidly until the water flows so fast that the valve on the right is lifted and closes. As a result, the flowing water closes its own exit.

The water that was still moving in the tube now causes high pressure in the ram. This overpressure is comparable to the situation when you close the tap quickly at home. Also then, “suddenly” the exit will be closed, but the water will still arrive. You will hear a loud “kloink” in the water pipe. This is called the “water hammer”, and from this the hydraulic ram gets its name. In the hydraulic ram, this water hammer is put to use: the overpressure opens the non-return valve at the top.

This valve leads to an air chamber, with the lift pipe connected to it, which transports the water upwards. A little water flows into the air chamber and the delivery tube. The function of the air chamber is to make the water flow even further. During the short time that the check valve is opened and water flows into the air chamber the air is compressed. When the non-return valve closes again, the compressed air forces the water up through the lift pipe.

When the water in the lift pipe almost comes to a stop, the overpressure disappears and the non-return valve closes. This whole process only takes a fraction of a second. In the final stage of the process, both the check valve and the outlet valve are closed. The water, which is still moving a bit, now has no way out, and “bounces” back, so to speak. This creates a negative pressure in the pump housing for a short time, which opens the outlet valve again. Then the whole process is repeated. This happens about once or twice a second.

An important advantage of a hydraulic ram is that it works fully automatically, as long as water is supplied. In practice, many applications are known in which rams have worked non-stop for years without failure. Modern applications of the hydraulic ram, such as those made by AIDFI in the Philippines (by the Dutch engineer Auke Idzenga) are made in such a way that maintenance is easy and inexpensive. For example, for the only moving part, in the exhaust valve, a door hinge is used.