We all know WOTters are the sportiest people in the world, but sometimes they need some extra exercise. This was achieved by fitting an old motor from a kid’s toy on an old rowing machine out of gym, connect to some batteries and we have renewable energy!

Because the motor from the kid’s toy is a three phase permanent magnet motor, it generates a 3 phase Alternating Current (AC) when rotated. This is very useful for high power motors such as in trains or big milling equipment, but not so much for small scale off-gird power. This is why the generator is connected to a ‘full bridge rectifier’, this takes the three phase AC input and converts it to Direct Current (DC). Cheers for AC/DC! The output DC of the rectifier is then connected to a lead-acid battery (also DC) and voilla; we can put muscle power into a battery!

Small off-grid systems often save solar energy in a battery and later convert that to 230 V AC. This can be done here too! So during the day one could use a solar panel and at night human power.

In the pictures above, the generator can be seen on the left. It is connected with gears and chain from a bike. This increases the rotational speed of the generator. Because the generated voltage is proportional to rotational speed, we can now generator higher voltages. On the right picture you can see two batteries in series (24 V). With higher voltages we can handle more power. With this setup, you could easily start a full sized diesel lorry (50 ton) if you row for a while!

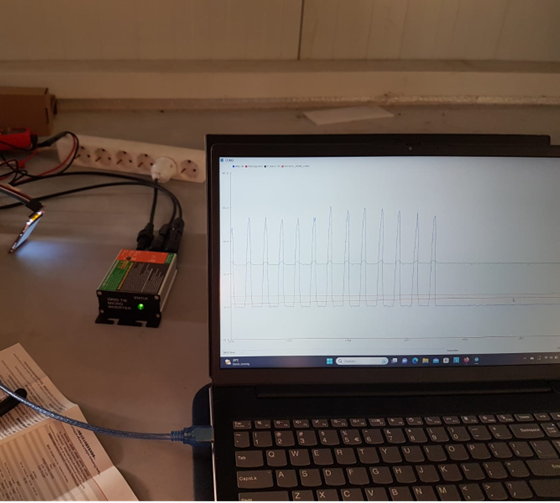

Of course not everyone has an off-grid setup or a lorry with empty batteries. The energy in the battery can also be injected into the grid. Below is a picture of the generated power on the screen (every peak is someone pulling on the rower). To the left is a small solar converter that can inject DC into the national grid. This way we are powering an infinitesimal bit of the world!