Windmills

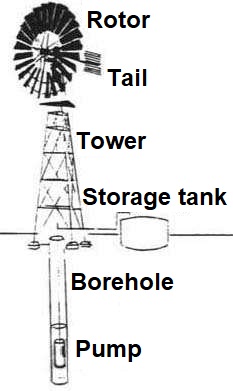

The different parts of a water pumping windmill

A windmill is made up of a tower and a head. The rotor, the tail vane, and a security system are all attached to the head. The rotor (a set of blades or sails) catches the wind and converts its energy into mechanical or electrical energy. In the case of small windmills, the main vane should keep the rotor in the wind. This allows the mill to operate in different directions. Sometimes the security system consists of a vane on the side or an angled vane with an eccentrically placed top. This will turn the rotor out of the wind at high wind speeds.

A water pumping windmill typically uses a piston pump. (The operation of this pump is generally explained in the chapter on the hand pump). A crankshaft or gearbox converts the rotary motion of the rotor in an up and down movement of the piston pump. A mill with this type of pump can be recognized by a large number of blades, usually somewhere between 8 and 24. This large number of blades is necessary because of the high torque required by the piston pump. Sometimes a transmission is added to increase the torque even more. Which makes it possible to pump water from deep boreholes. The more blades a windmill has the slower it will turn, which is referred to as a slow turning windmill.

A water pumping windmill is often placed on top of a borehole or near a river. Besides the mill a tank is required, where water is stored as a buffer for when there is no wind. The ferro cement tank at the WOT site is one example. The water provided by the windmill can be used for domestic use, livestock or irrigation. The storage tank must be sealed to prevent contamination of the water with diseases if the water is used for drinking.

The current water pumping windmills at the WOT in operation are the Oasis, the Kijito, the Cretan and the Diever

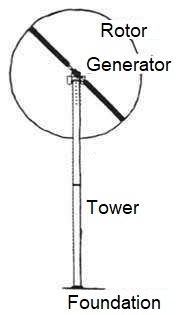

Electricity-generating windmills

An electricity-generating wind turbine is also called a wind turbine. The generator is integrated into the head of the windturbine. The rotor consists of only a few blades to be able to have a fast running windmill. This is required since the generator requires high RPM and there is not much torque necessary.

Just like with the water pumping windmills a buffer is required for times when there is no wind. In case of an electricity-generating windmill in remote areas, this is in the form of batteries. Only the big commercial wind turbines are connected to the grid.

At the WOT there are two wind turbines: the Virya 3.3 and the Virya 1.04